Quanta Factory Leverages Private 5G

for

Safety AI, AR, and End-of-line Inspection

Smart Factory applications to accelerate digital transformation

Customer Challenges

The lack of deployment

flexibility with wired

networks

The need to ensure

worker safety around

machinery

The losses incurred

from production line

shutdowns

The high technical

barrier of entry

Success at a Glance

- Safer workplace environment

- Easy monitoring of multiple production lines

- Real-time display of work instructions

- Enhanced quality inspection and assurance

- Lower technical threshold

- Streamlined training process

- High mobility and trackless navigation

Solutions

Safety AI for Robotic Arms

To ensure workplace safety, AI is used to set up virtual fences to stop robotic arms and send alarm notifications when operators accidentally trespass into danger zones.

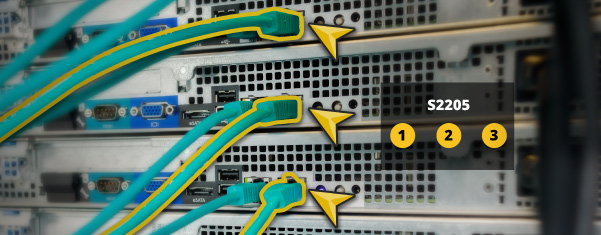

AR for Information Visualization

To easily monitor hundreds of server racks at a glance, 5G signals are used for positioning and AR technology is used to display machine operating status.

AR for Cabling Installation

To lower the specialist background threshold required for technicians, image recognition and AR are used to display cable model information and installation instructions.

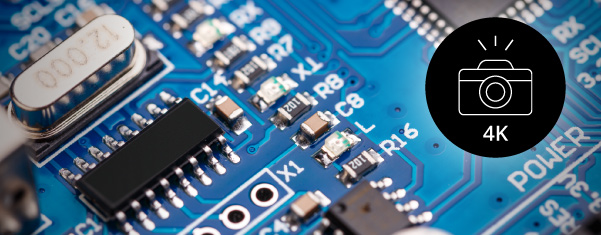

Product Image Archiving

To provide control for future maintenance needs, 4K images of all motherboards are taken and recorded by industrial-grade cameras before leaving the factory.

AR for Training & Repair

To improve maintenance efficiency, AI and AR are used to provide step-by-step visual repair guides on how each task should be carried out in real time.

AMR Material Transportation

Through the deployment of 5G signals throughout the factory, autonomous mobile robots (AMRs) can be controlled by a central management system for material transportation.

Solution Architecture Overview

Private 5G Network